No products in the cart.

What You Need to Know About Room Airflow Management

The original version of this article was published on MissionCriticalMagazine.com, titled Managing Airflow at the Room Level. You can view it here.

Room level airflow management is fraught with misconceptions and half-truths, making it the least understood aspect of airflow management, although it is ironically the most important. While it’s fairly well understood that the first 3 levels, or R’s, of airflow management refer to implementing solutions such as brush grommets, blanking panels, and containment for the Raised Floor, Rack, and Row levels, respectively, the Room level isn’t quite as simple. This is largely due to the fact that the changes required are invisible, except on occasion for the displays on cooling units.

For clarity, Room level airflow management is better defined as cooling optimization, which refers to the process of making adjustments to the cooling system controls. If done well, this process will improve energy efficiency (resulting in reduced operating costs), improve cooling capacity, improve IT equipment reliability, and defer capital expenditure. It’s important to note here that without cooling optimization (i.e. Room level airflow management), every solution that has been implemented up until this point, such as the products listed above, is an expense. While they may have improved IT intake air temperatures, the financial and capacity benefits are left on the table. The only way to realize energy savings from airflow management improvements made at the Raised Floor, Rack, and Row levels, is through cooling optimization.

And while the process of cooling optimization is typically a manual and iterative process, it’s also important to note that utilizing solutions such as IR thermometers or environmental monitoring will ensure IT intake temperatures do not exceed their recommended or allowable thresholds. More so, some monitoring solutions can even provide advisement on specific optimization steps that can be taken, but we’ll jump into that later.

Matching Cooling Capacity with IT Load

Airflow management alone does not save you any money on cooling energy costs, instead it improves IT equipment intake air temperatures and creates the conditions where changes to the cooling infrastructure are possible. Reason being, if you have implemented airflow management solutions at the Raised Floor, Rack, and Row levels correctly, you should now have an excess of conditioned supply air in your cold aisles and all IT equipment intake air temperatures will be excessively low. This is because there is no longer any mixing of exhaust air with conditioned air, and vice versa. The next step is to match the flow rate of conditioned air as closely as possible with the demand flow rate required by the IT equipment. This is done by lowering fan speeds, raising cooling unit temperature set points, or turning cooling units off altogether. This is often an iterative process of making adjustments to controls, allowing the system to equalize, and then making additional adjustments if needed. In addition, as data centers are dynamic environments, this will also be an ongoing process – not just a one-time event. Each time additional airflow management improvements are implemented, or significant IT equipment changes occur, there are opportunities for optimizing the cooling infrastructure.

Room Level Airflow Management (Cooling Optimization) Best Practices

As mentioned above, the typical steps that need to be taken to properly match the cooling capacity of your data center with the IT load (i.e. optimize the cooling infrastructure) are listed below:

- Reduce fan speeds for units with variable frequency drives (VFDs) as much as possible without exceeding the maximum allowable IT equipment intake air temperature

- Raise cooling unit temperature set points as high as possible without exceeding the maximum allowable IT equipment intake air temperature

- Expand the allowable relative humidity (Rh) band to prevent cooling units from “fighting” with each other (wasting energy by one unit trying to dehumidify while another unit tries to humidify)

- Turn off excess cooling if cooling units don’t have VFDs

- Note: If cooling units are equipped with VFDs, energy savings are greater with 10 cooling units running at 50% fan speed than 5 cooling units running at 100% fan speed

After any significant airflow management improvement or IT load installation or removal, there’s an opportunity to evaluate these Room level controls to ensure efficient operation and sufficient redundant capacity.

Utilizing Monitoring Solutions to Inform Optimization Decisions

A wise man by the name of Ken Brill once said that when it comes to data center cooling, it’s as simple as “power in, heat out always.” Meaning that every kW of power consumed by any equipment in a computer room becomes a kilowatt of heat that needs to be removed from the computer room and ultimately the data center building. This includes all power conversion and distribution losses as well as every kW of electricity consumed by the IT equipment.

While data center cooling is a science in its own right and can be quite complex at times, this concept reminds us that it can be boiled down to what goes in, in terms of power, must come out in terms of heat. Therefore, it’s important to monitor the power being demanded by IT equipment (i.e. the IT load) to properly match it with the cooling being supplied by cooling units (i.e. cooling capacity), as noted above. Utilizing solutions that can monitor both the power and cooling infrastructure will help in creating this balance.

Secondly, monitoring the thermal performance of a computer room is essential in the cooling optimization process. When making adjustments to the cooling infrastructure, you will need to closely monitor the IT equipment intake temperatures to make sure they do not exceed their recommended or allowable limits, as outlined by ASHRAE and/or the manufacturer. This can be done with an IR thermometer or IR camera, but may be time consuming as it can only be done on a per cabinet or aisle basis. One big cautionary remark with using an IR thermometer or IR camera is that these infrared tools measure surface temperature, not air temperature. And if there is a highly reflective surface, you may experience some incorrect readings due to the reflections. While use of infrared tools can give you an indication of temperature issues, they are not monitoring the temperature of the airflow itself.

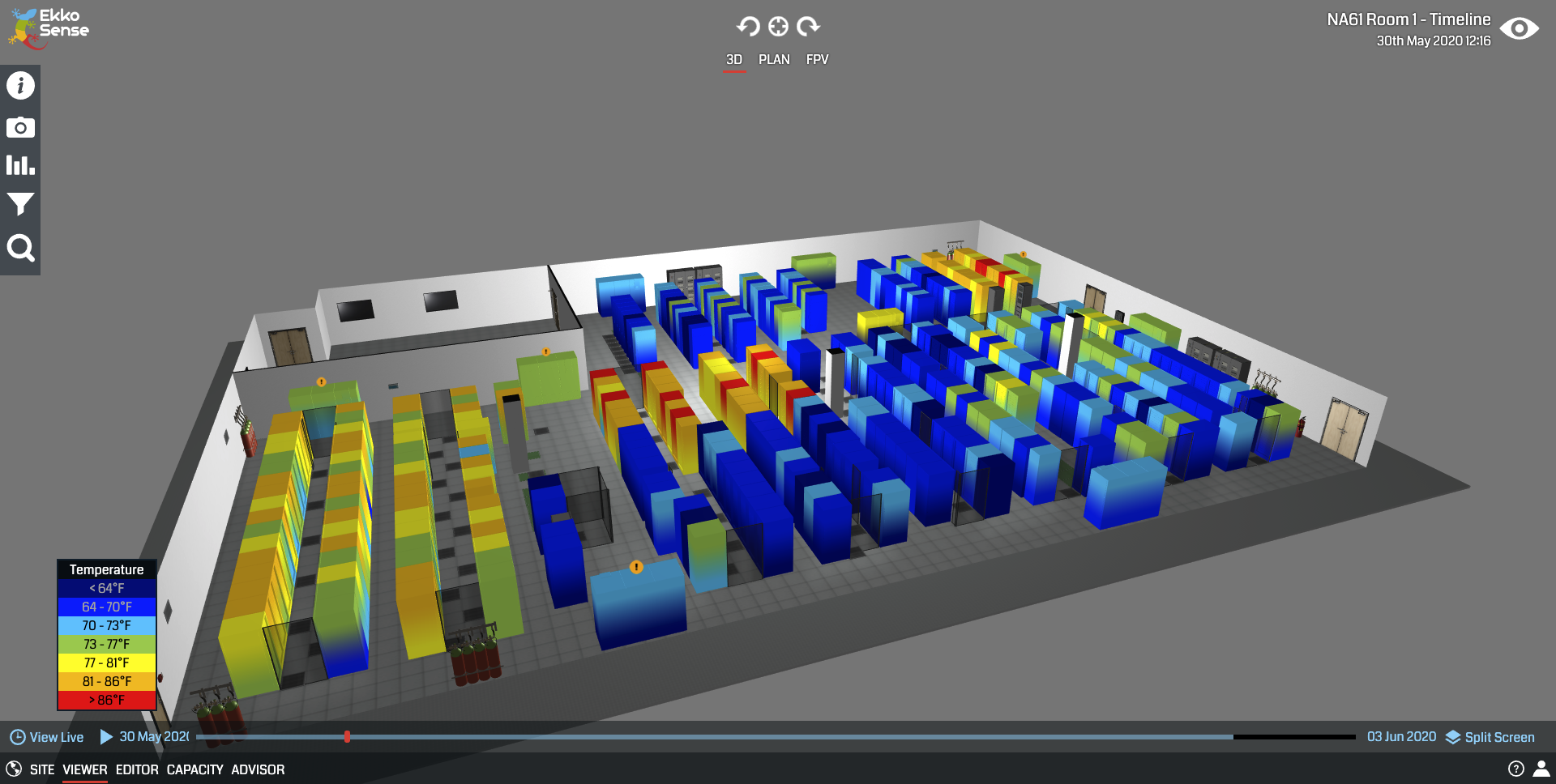

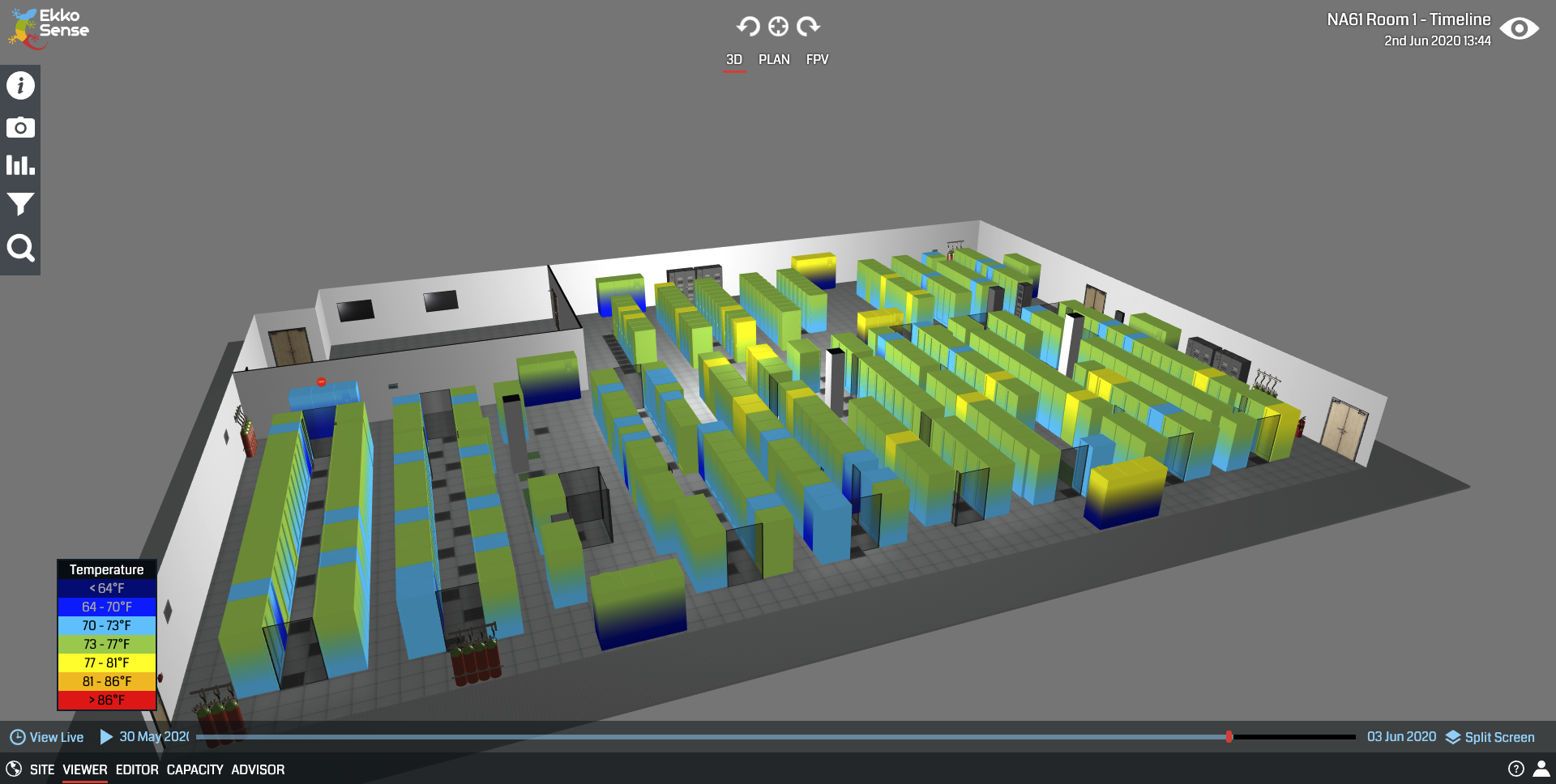

Due to these circumstances, the easiest way to do this at the full Room level is to utilize a monitoring solution with sensors placed at the tops and bottoms of all cabinets. This will give you a site-wide view of your data center’s thermal performance. Moreover, while being able to monitor temperatures site-wide is the bare bones of what’s needed, some monitoring solutions have taken this a step further with 3-D visualizations that will display a digital twin of your data center and its real-time thermal performance.

Optimization with AI and Machine Learning Algorithms

Let’s face it, AI and Machine Learning are buzzwords that have made the rounds throughout the industry as a panacea to many data center and IT related issues. While they may come up short on many of their perceived or marketed promises, airflow management and cooling optimization is where this technology really has a chance to deliver. Utilizing this technology can help visualize airflow management improvements at the Raised Floor, Rack, and Row levels, analyze data being collected from sensors, and provide advisement on cooling optimization decisions at the Room level. There are solutions available that have pioneered this use-case for AI and Machine Learning that couples the monitoring aspect with cooling optimization in the form of a virtual cooling advisor. It’s worth taking a look at these solutions to take out some of the guesswork in the cooling optimization process.

Conclusion

Room level airflow management is not actually airflow management in the literal sense, but instead cooling optimization. Nonetheless, Room level airflow management is a necessary step and the only way to realize energy savings from airflow management improvements made at the Raised Floor, Rack, and Row levels. Remember, every solution that has been implemented up until the Room level is an expense. It is only when you check in at the Room level and make changes to the cooling infrastructure that you can reap the benefits in the form of cooling energy savings, improved cooling capacity, improved IT equipment reliability, and deferred capital expenditure. Efficiency cannot be purchased; it must be managed. Also remember, cooling optimization is an iterative and ongoing process that boils down to matching the cooling capacity with the IT load of the computer room. And although this will be a manual process in most cases, utilizing monitoring solutions that give you a look at the power, cooling, and thermal performance of your data center will help guide your optimization decisions, and in some cases advise on specific steps that can be taken.